Feasibility analysis

Analyze professionally ==> Less effort and less cost

The feasibility of a texture is often checked far too late in the project, i.e. only after or in the middle of the production of the tools. As a result, OEM design requirements may no longer be fully implemented or only with delays and correspondingly higher costs.

The concept / design of the injection molding tool must be changed and adapted in its production. The feasibility analysis should always be carried out before the production kickoff of the injection molding tool, even if no texturing company has yet been nominated for the project.

The following requirements are checked in this analysis:

The analysis contains suggestions as to how the texture project can be carried out in the required high quality.

Do you feel insecure and want to get professional support? Then we are your independent partner for feasibility studies.

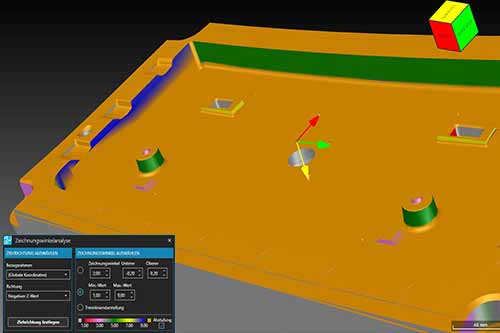

Demolding analysis

Detailed analysis ==> Higher surface quality without avoidable defects

The demoulding analysis determines the surface quality of plastic components. In practice, scuff marks often arise due to the abrasive damage to the texture when the plastic component is demolded from the injection molding tool, because the minimum draft angle was not correctly calculated and / or extreme instead of standard injection molding parameters are used in the production of the plastic components.

Furthermore, in some cases insufficient minimum draft angles in the case of core shrinkage (shrinking of the plastic onto the steel during the injection molding process) are used as a basis. This analysis shows the feasible minimum draft in all areas of your plastic components or injection molding tools.

Both the feasibility and the demolding analysis should always be carried out timely, even if no texturing company has yet been nominated for the project.

It is important that an approval for the demoulding analysis is received by your customers or end customers (OEM) before you start manufacturing the injection molding tool.

Prevention is better than unnecessary, expensive optimization loops! Request a professional demolding analysis now.

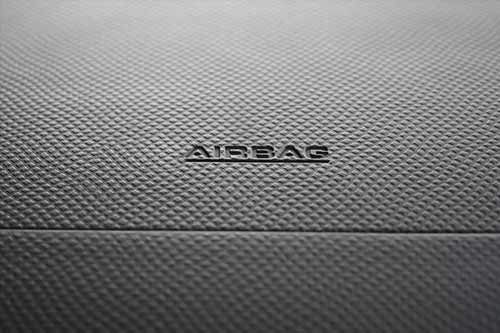

Surface problems

Independent analysis of plastic components with surface defects

Our longstanding experience in the texturing business shows that many customers have insufficient know-how in terms of identifying the causes of texture surface problems and their possible solutions.

The texturing company often blames the steel material and / or the injection molding process for the surface problems. But this does not always have to be the case.

Do you need an independent analysis of plastic components with a defective appearance in the case of chemically etched textures?

Do not hesitate and contact us.