Finish tool projects safely and sustainably

Consideration and compliance with all decisive factors

Our services:

Analysis

Feasibility

Before the tool design is approved, we check the data on the plastic component and optimize it if necessary. This is an essential step in order to avoid surface defects and high tool modification and optimization costs.

Demolding

Before the tool design is approved, a correct and binding demolding analysis based on component or tool data must be carried out. Problems when ejecting the component during the injection molding process and damage to the component surface are avoided.

Moldflow

Optimized design, temperature control and injection position as a result of the analysis serve to prevent defects such as air pockets, weld lines or sink marks. Significantly improving the structure and appearance of your components will lower the overall cost of the tooling project.

Validation

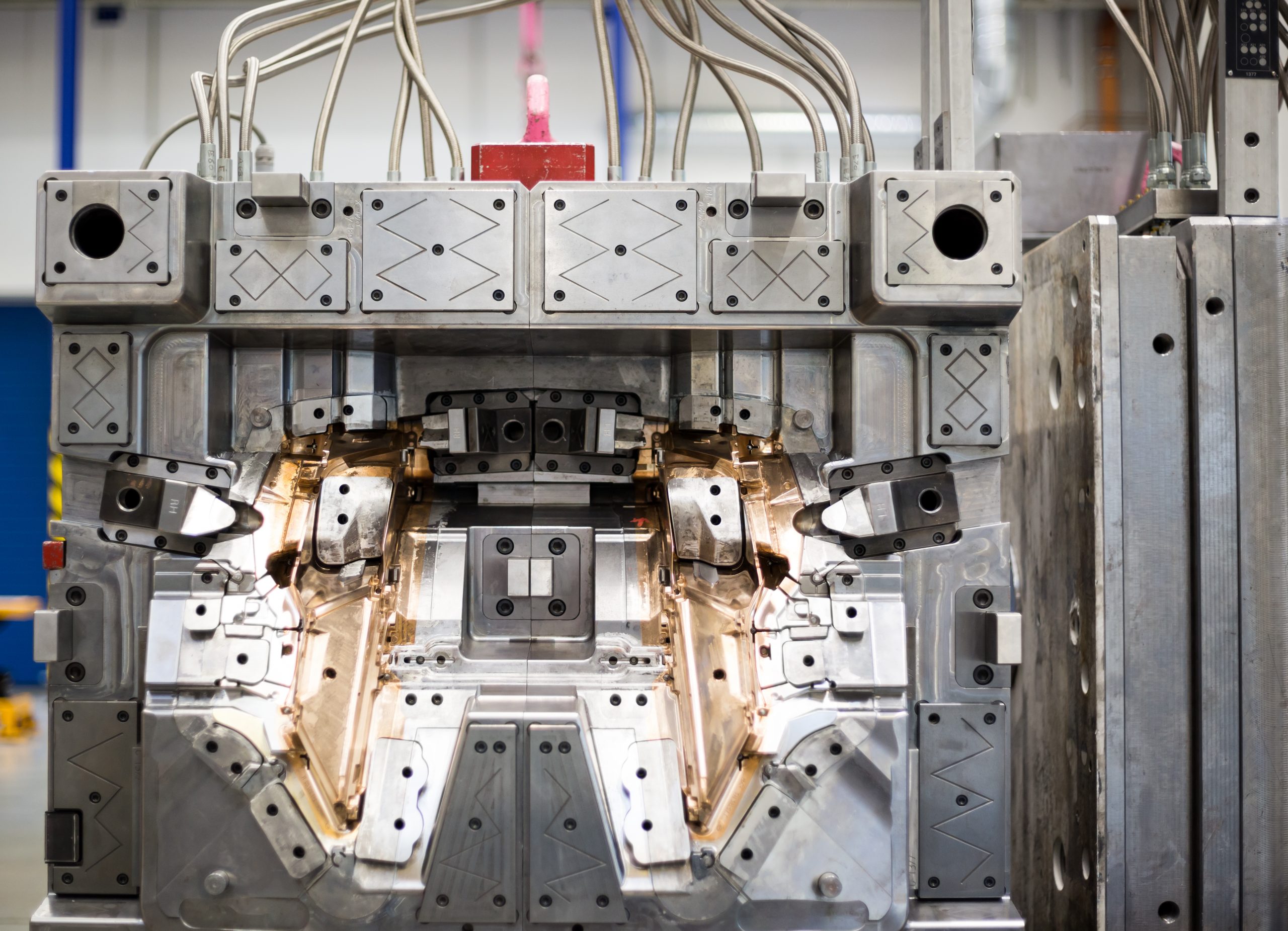

Tool construction

We design your injection molding tools (3D + 2D) with the help of Unigraphics, Catia and ProEngineer.

Meeting at tool manufacturer

For a smooth process, meetings with tool manufacturers to check, validate and approve the design status are essential.

Rapid Prototyping (3D-printing)

Prototypes via 3D printing in the right material to test and validate requirements for your plastic component before the injection molding tool is manufactured.

Tool tracking

Status control

Ensuring compliance with the schedule by spot checks at tool manufacturers.

Action plan

Development and control of measures in case of occurring delays.

Reporting

Recording of the actual status of the tool manufacturing progress with photo documentation.

Tool quality

Measurement

3D

CMM

Injection trials

Assistance including support for solving quality problems

Finish

Optimizations, modifications, repairs of injection molding tools