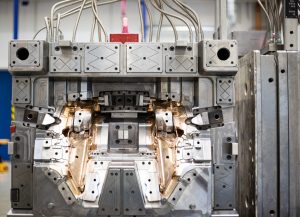

Change strategy in the procurement of injection molding tools

Maximum focus on transparency

The Covid19 pandemic brings many companies to the edge of the abyss in a highly dynamic way every day due to delivery delays and stops.

This struggle for survival is additionally intensified by less incoming orders and lower production volumes. Strongly increased air freight prices for transports from China to Europe as well as the suspension of ship transports lead to exponentially high costs and greatly reduced freight capacities.

It is becoming a balancing act to hold together the global supply chains, which have become more and more complex over the past few years.

We support you in the development and implementation of a sustainable change strategy in the area of tool procurement.

Strategy development

- Clear company vision

- Environment analysis

- Company analysis

- SWOT analysis + actions

- Definition strategic goals

Strategy implementation

- Auditing and selection of tool manufacturers

- Agile management of tool projects

- Continuous tool tracking

- Transparent risk management

Permanent risk management

Only those companies that adjust their procurement strategy and supply chain in a targeted manner and implement permanent risk management will survive the current and future crises.

More and more injection molding tools are being procured in China because of the cost and delivery time advantages that still exist, even if this strategy has been in decline since the 2009 financial crisis.

The pandemic has intensified this tendency and has shown more than ever that single sourcing as a procurement strategy is very risky.

We ensure that risk elements are identified and removed from your procurement process or tracked with maximum transparency and security.

Implement reshoring strategy successfully

Implement reshoring strategy successfully

Multiple sourcing reduces the risk of failure by spreading it across different sources. Despite the savings for companies, the risks associated with outsourcing production are no longer worthwhile.

In addition to multiple sourcing, transparent risk management and make or buy, reshoring will become increasingly relevant in the future. The Far East, including China, are losing their importance for European OEMs. As a consequence, regions such as DACH and EU countries will start to rethink and to reorganize their procurement strategy.

Maximum focus on transparency

We connect your purchasing team with European tool manufacturers and ensure that cost and delivery targets are achieved by providing maximum transparency throughout the entire procurement process and project flow.

We are experts and, thanks to our longstanding practical experience, we have broad know-how in the areas of tool making and plastic injection molding.